The centerline material is trying to return to its original shape, yet is constrained by the unyielding material on either side. The cause of springback is uneven stretching of material during a bend. This relates strictly to the number of degrees required in a particular bend. The relationship between outside diameter and wall thickness has an important bearing on selecting a die. It's important to use accurate calipers when measuring this value a tape measure or well-trained eye are not accurate enough in this case. For pipe: Schedule determines wall thickness. Wall thickness is the distance between the outside diameter and the inside diameter of the pipe measured in thousandths of an inch. The inside diameter (ID) is the longest distance across the inside dimensions of a tube or pipe. The outside diameter (OD) is the distance across the extreme outside dimensions of a tube or pipe. The software then uses the stretch/compression data to properly calculate the amount of material in each bend as well as the proper bend locations. This value is obtained using a calibration test, by bending a test piece of material and measuring the resulting legs.

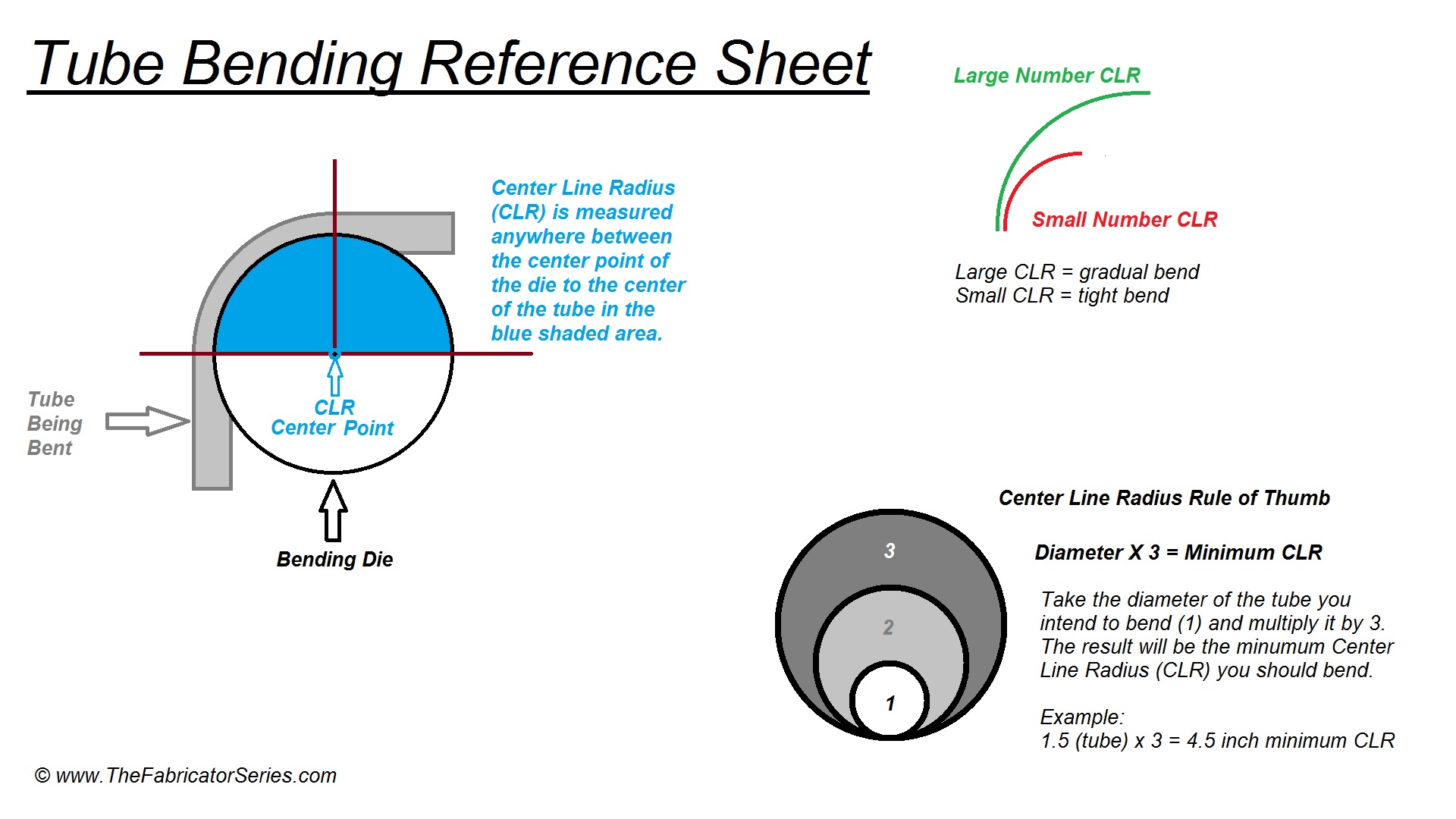

When using Bend-Tech Software, this value is used to specify how much stretching and compressing will occur during each bend. Because of this stretching, you will find that the CLR of a bent piece of material is slightly larger than the CLR listed on the die.Ĭalibrated Center-line Radius (Calibrated CLR): Material will spring or stretch open after it is bent think of coiling a wire around a pencil – release the wire and it will fall off the pencil.

This value is the radius you obtain when bending with the die. When choosing a die, factors that will affect the CLR you choose include the material type and grade to be bent, wall thickness, the OD, the application or design of the end product, and overall appearance required.Īchieved Center-line Radius (Achieved CLR):

0 kommentar(er)

0 kommentar(er)